01. A better decision-making: the challenge of technology selection

In the early stages of developing a chemical process, selecting the reactor technology is a fundamental decision. It determines technical feasibility, overall performance, safety, as well as investment and operating costs.

Too often, this choice is postponed or made by default due to insufficient data, which can lead to cautious solutions that penalize industrial performance.

To meet this challenge, Processium, together with its academic and industrial partners, has developed PROCIP: a digital tool that makes the selection of reactor technologies more reliable and faster from the very early stages of a project.

As PhD Estevan Tioni – one of the engineers behind the project – points out:

« Technology selection was often done by default, with reactors that were considered ‘robust’ but suboptimal. We needed a tool that could justify, objectify, and anticipate these decisions. »

02. PROCIP: a unique tool at the service of our customers

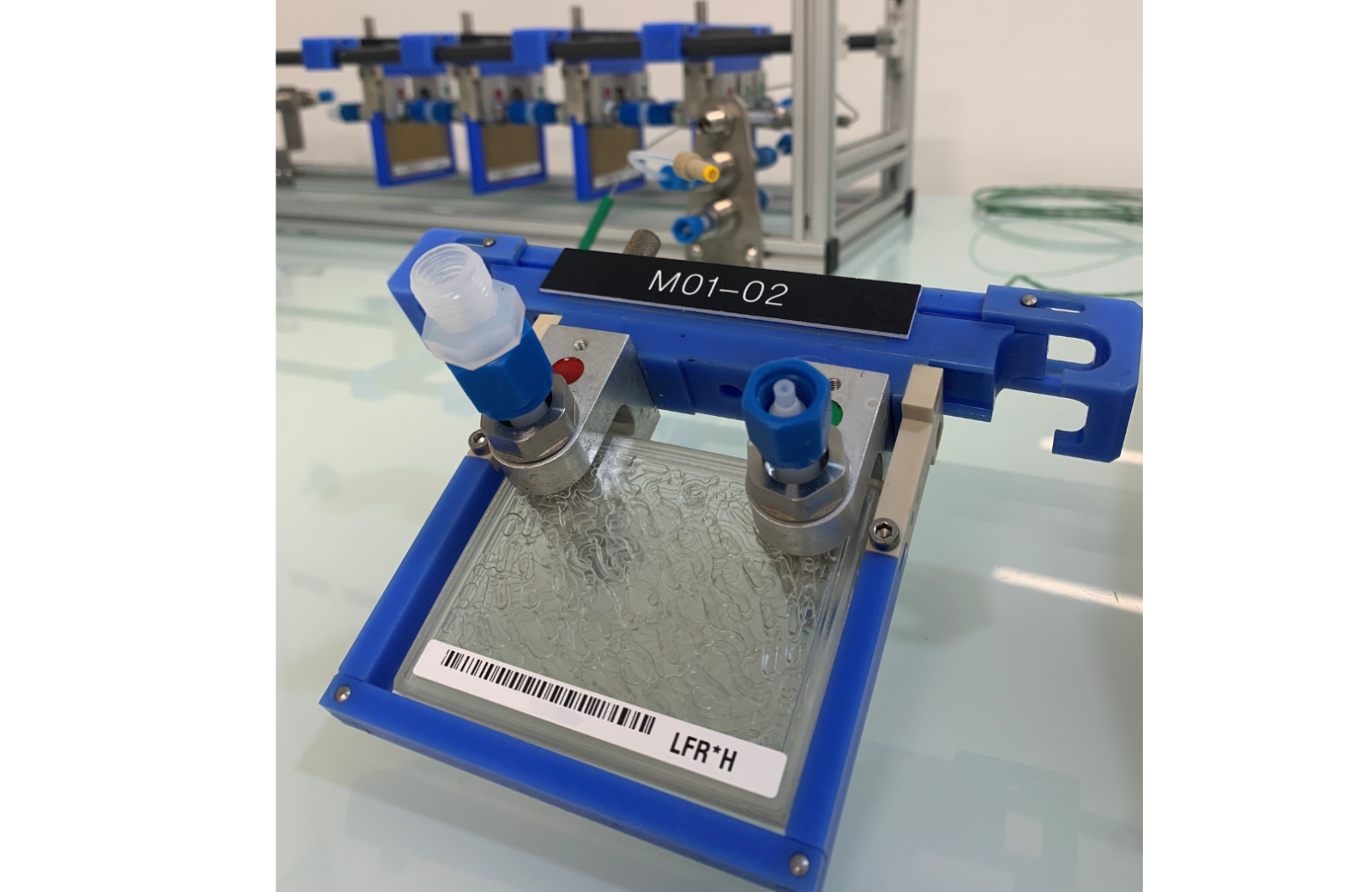

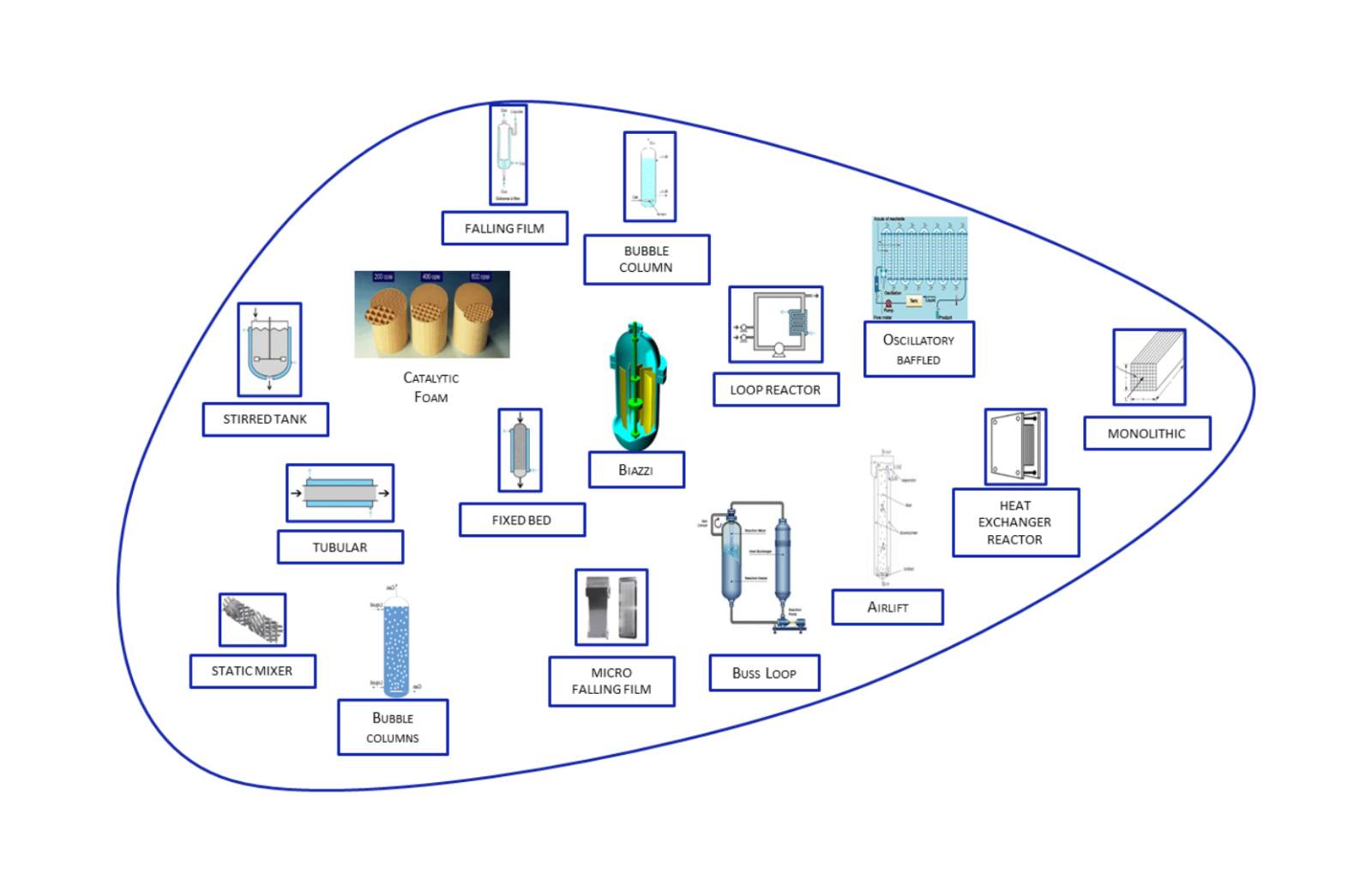

PROCIP is the result of collaboration between leading industrial companies (Elkem Silicones and Solvay), several laboratories (the CNRS, the Catalysis, Polymerization, Processes and Materials Laboratory in Lyon, the Process Engineering Laboratory in Nancy, and the Chemical Engineering Laboratory in Toulouse), as well as public partners (the French National Research Agency and Axelera). PROCIP is based on a robust database covering more than 300 types of reactors, grouped into 20 technological families — from traditional stirred tanks to innovative microchannels.

Its goal? To objectively compare the various options available, whether conventional or intensified, to help decision-makers identify the most suitable process solution.

As explained by PhD Estevan Tioni, who initiated the project, two major motivations guided its development: « the goal is to promote intensified technologies with an objective basis for comparison and to be able to estimate as early as possible what the final process might look like by anticipating costs, constraints, and industrial scenarios. »

PROCIP is not commercialized because it is an expert tool that requires the know-how of reaction process engineers. At Processium, our specialists operate it on behalf of our customers so that they benefit not only from the power of the tool, but also from the expertise of our engineers in order to:

- Make decisions earlier and with confidence

- Save time in developing their project

- Base their choices on performance rather than habits or biases from experience

- Reduce the financial and technical risks associated with industrialization

03. How does it work?

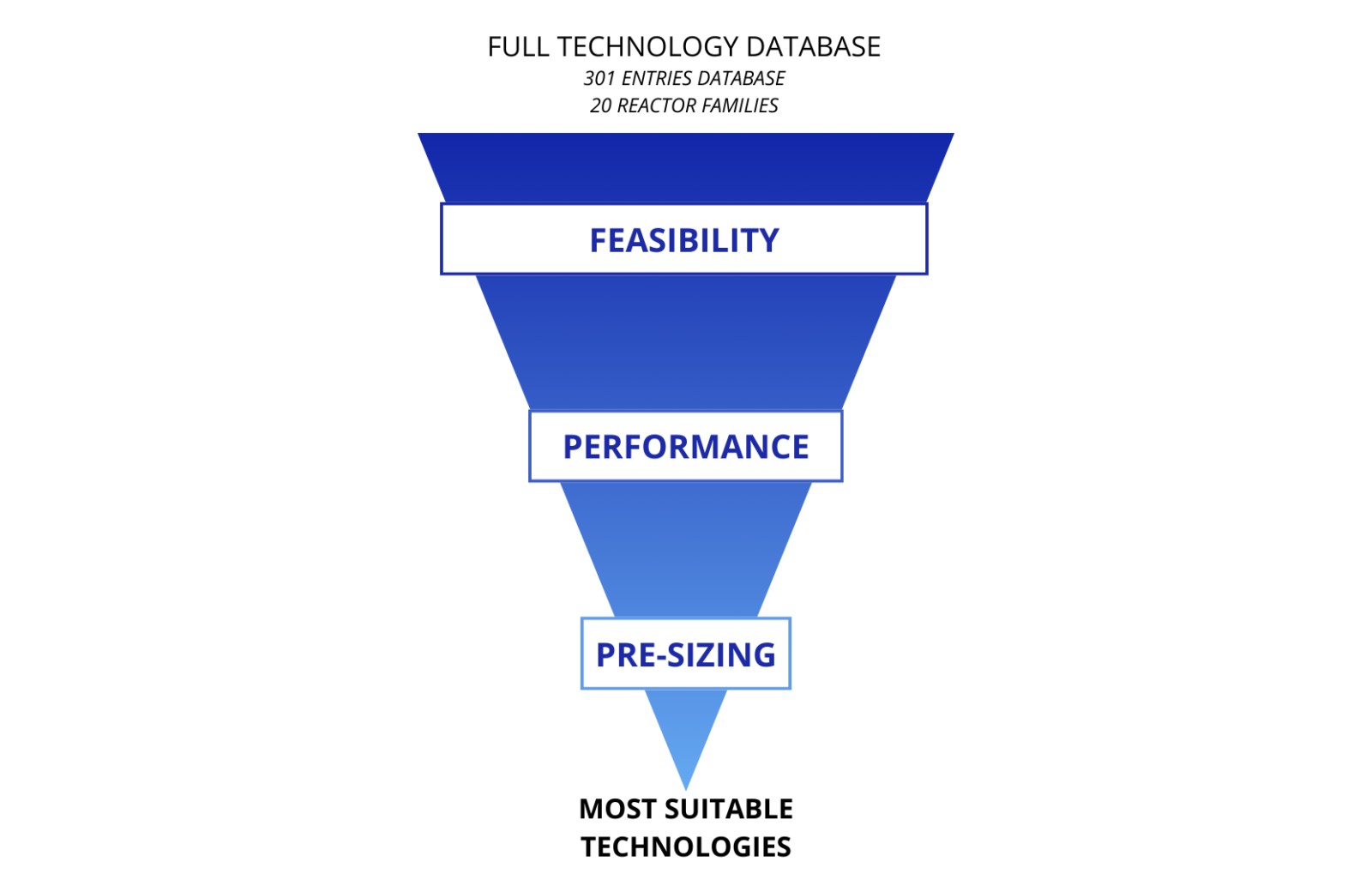

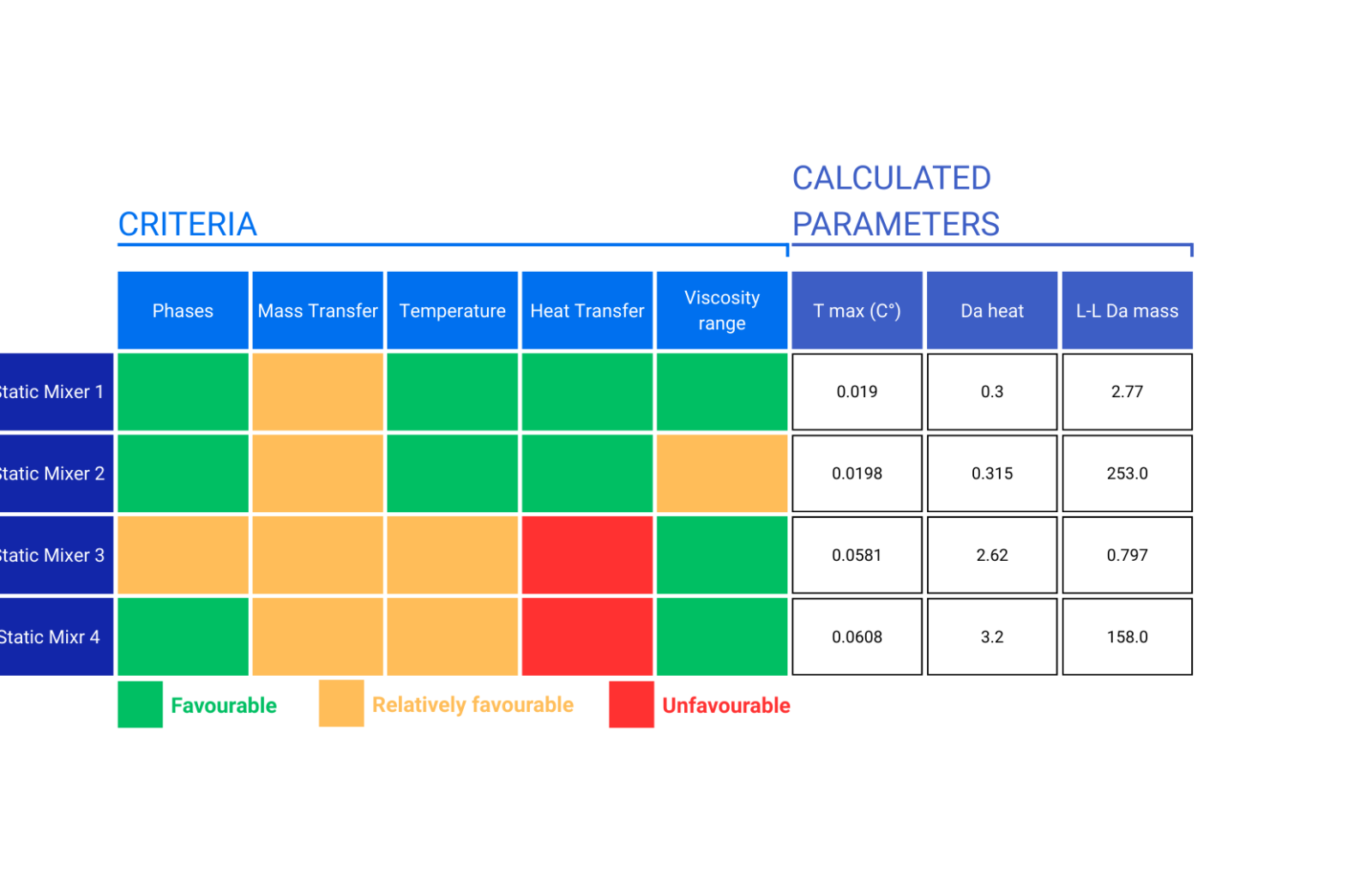

PROCIP evaluates each technology according to 11 key criteria, which combine:

- Feasibility (technical conditions under which a reactor can operate sustainably and safely)

- Performance (the reactor’s ability to ensure efficient heat and mass transfer, which are essential for effective reaction and precise control)

- Industrial pre-dimensioning (a preliminary estimate of the dimensions and capacities required for large-scale production)

Using a minimal dataset – compounds, reaction, a few experimental measurements (temperature, pressure, conversion), and key industrial data (flow rate, tonnage) – the tool performs the following:

1. Analysis of characteristic times: comparison between the time required for the chemical reaction and the capabilities of each technology to efficiently transfer heat and matter.

2. Multi-criteria filtering: elimination of unsuitable technologies according to 11 evaluation criteria.

3. Objective ranking: prioritization of relevant technologies with preliminary sizing estimates.

PROCIP’s strength lies in its ability to provide a comprehensive, neutral, and exhaustive overview of available solutions. Whereas an expert may naturally favor a technology they are familiar with, PROCIP puts all options on the table, including those that might be dismissed too quickly. Of course, the results are never taken “at face value”: they are interpreted, challenged, and validated by our engineers, who compare them with the customer’s industrial reality.

In summary, PROCIP makes it possible to transform a limited set of data into a reasoned, robust, and performance-oriented choice from the very beginning of a project.

04. Tangible results, measurable gains

PROCIP is not just a decision-making tool: it is an industrial performance accelerator that has already been proven in the field.

A case in point: a chlorination reaction, initially conducted in batches, showed a yield of 78% after 5 hours of reaction. With the help of PROCIP, the team identified a continuously intensified technology. The results were immediate, as PhD Estevan Tioni explains: “PROCIP highlighted a potential performance improvement that we might not have tested otherwise. We went from 78% to 90% yield with an operating time reduced by a factor of 2,500!”

Other projects (polycondensation, resin production, etc.) have confirmed PROCIP’s impact on Processium’s customer projects: better yields, increased safety, and more compact and energy-efficient processes.

05. A constantly evolving tool, serving customer needs

Because our customers’ needs are evolving, PROCIP is evolving as well. The next version will enable the management of complex reactions involving several products,to optimize not only conversions but also selectivities.

« We are working on an improved version capable of handling multiple reactions, not just conversions. But before applying it to customer projects, we want to validate the results with cases we already know. » – PhD Estevan Tioni

Connected to our other proprietary tools such as e-thermo, PROCIP is part of an integrated approach, where data consistency is ensured at every stage of process development: from technological evaluation to modeling and industrial validation. This complementarity makes Processium a player capable of offering an integrated, robust, and optimized approach to industrial process development.

06. Processium turns uncertainty into a competitive advantage

In an environment where every decision impacts performance, costs, and time to market, Processium positions itself as a trusted partner for today’s and tomorrow’s manufacturers. Thanks to PROCIP—an exclusive tool we use as part of our services—our engineers support our clients in:

- Reduce financial and technical risks by securing technological choices from the earliest stages

- Accelerate chemical process development and industrialization to save valuable time in bringing products to market

- Improve productivity and yields by identifying the most efficient technologies

- Optimize investments by directing projects toward the most suitable solutions in terms of CAPEX and OPEX

- Contribute to more efficient and sustainable chemistry by developing more compact and energy-efficient processes.

With Processium, you not only benefit from a cutting-edge tool, but also from tailor-made support where scientific rigor meets industrial experience. We transform your uncertainties into clear decisions and your projects into concrete successes.