Fermentation: a sustainable alternative

Faced with the need to reduce dependence on fossil fuels, fermentation is emerging as a sustainable solution. This process relies on the action of micro-organisms (bacteria, yeast, fungi) to transform renewable raw materials into molecules of interest. Fermentation processes take place under milder conditions, offering an environmentally-friendly alternative.

Interest in fermentation is growing all the time, particularly as part of the transition to greener, more sustainable chemistry. This process can be used to produce biofuels, pharmaceutical molecules, alternative proteins and biomaterials, contributing to a more environmentally friendly industry.

A tailor-made laboratory to meet new industrial challenges

In 2024, to support this transition and offer its customers a complete range of services, Processium began work on the creation of a laboratory specializing in fermentation. However, fermentation processes present specific technical challenges, such as the management of microbiological contaminants, the stability of strains, the control of culture parameters (pH, oxygen, temperature) and the optimization of purification stages. The laboratory has therefore been designed to incorporate these requirements and offer optimum working conditions.

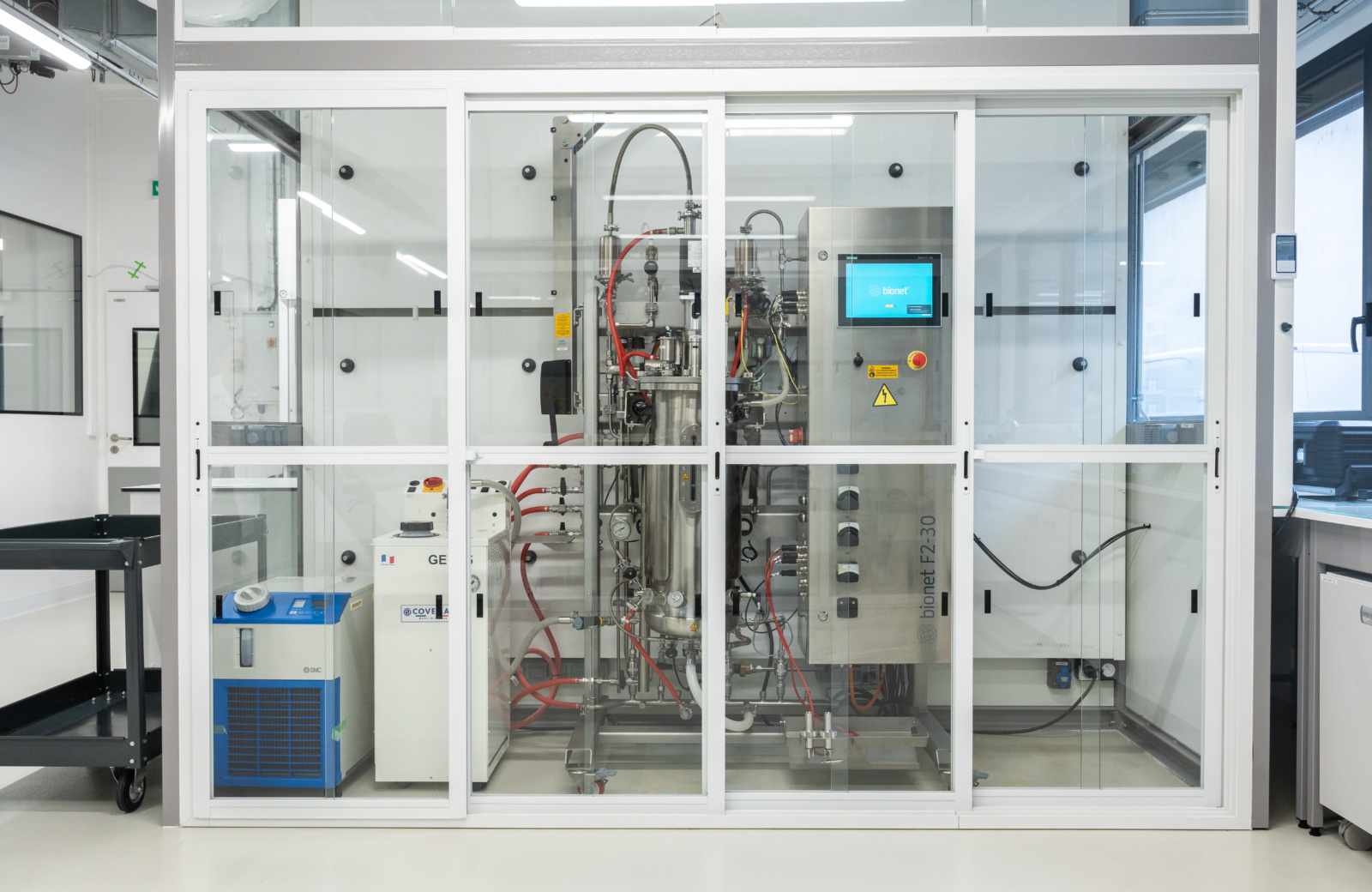

The design and selection of equipment was supervised by a team of engineers and technicians specialized in fermentation. The laboratory is equipped with three 5L and two 30L fermenters, allowing for a progressive scale-up, as well as all the ancillary equipment required for the smooth running of a fermentation laboratory. Every detail has been designed to ensure compatibility with the handling of genetically modified strains (GMO class 1).

An extensive offering for more sustainable industrial processes

Since its creation, Processium has supported its customers in the development and industrialization of innovative processes, including processes that involve a fermentation stage. Until now, Processium’s work in this field has focused mainly on the downstream process, developing and optimizing the purification stages. The opening of this laboratory on 1 January 2025 marks a strategic change, enabling the company to work on the entire process development cycle, from fermentation to the production of purified samples, integrating purification and optimization of the entire process.

This laboratory represents a key step in Processium’s development, reinforcing its position as a major player in industrial process development. Thanks to the support of Technip Energies and the involvement of its specialized team, Processium intends to play a key role in this rapidly evolving industrial ecosystem, supporting its customers in the development and optimization of fermentative processes, while guaranteeing overall process optimization and reduced environmental impact through Life Cycle Assessment studies.