01. Project success linked to adaptability

December 2021, the discussion started between Processium and the German giant Siemens about a large-scale project for the American 3M, famous for manufacturing many everyday objects through its well-known brands such as Post-It or Scotch. For the project purposes, Processium has been given the task to carry out an experimental performance validation of the process designed by Siemens. However, in order to carry out those tests in a representative industrial scale and to meet the project’s requirements, a made-to-measure distillation unit needed to be designed.

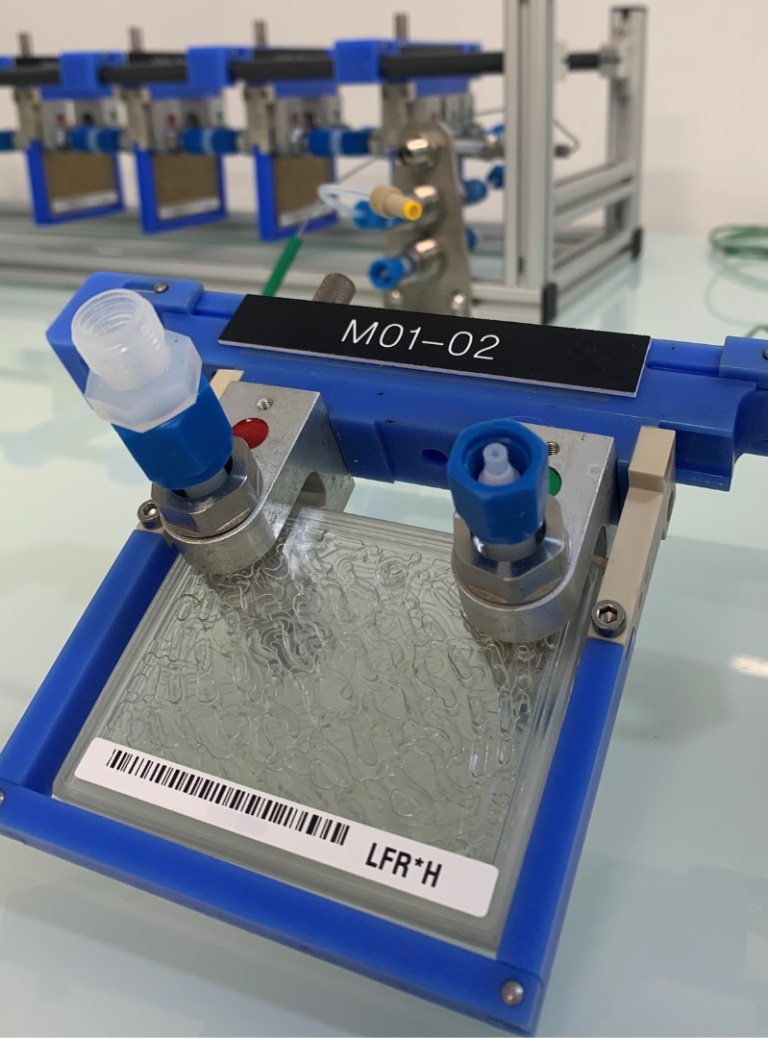

Once the service contract was signed during the 2022 summer, no less than fifteen weeks and €120k investments, co-financed with 3M, were needed to develop and install such complex distillation pilot. Naturally, the equipment construction was carried out in partnership with Pignat, Entreprise du Patrimoine Vivant and major specialist in the pilot equipment market.

02. Startup of the distillation pilot

To meet the demanding technical specifications of this project, the pilot design studies started shortly after purchase order reception. At the same time, security studies (HAZOP) needed to be implemented by Pignat and Processium to ensure a 24/7 secure automated operation working without human supervision. In December 2022, after two weeks of assembly, the new equipment was finally installed in Processium’s laboratories. Less than four months after receiving the Siemens purchase order, the pilot was ready to enter its testing phase.

To make sure the requirements are fully respected, this batch distillation column has been built with many specific features. Firstly, its 50 mm diameter gives a good representativeness with the expected industrial scale, as well as an adequate productivity. In addition, the column has an efficiency of more than 100 theoretical stages which, together with its 24/7 operation, allows it to test very complex separations with very long ramp-up times.

03. Successful results for the tripartite project

On January, the 23rd 2023, Processium’s experienced laboratory technicians started to test the custom-made functional pilot. One month later, the results are more than positive as the very stringent quality specifications are reached. Moreover, the results exploitation of these tests also help recalibrating the Siemens simulations so that they were more representative of the final obtained results and to ensure better industrial extrapolation.

A few days later, 3M congratulated the Processium team for its efficiency and the quality of the obtained results.

Processium now has a new batch distillation pilot that can perform extremely demanding separations.

04. In a nutshell

- 4 months to develop and install a pilot

- 100 theoretical stages distillation column

- 24/7 batch mode

- 6 weeks of pilot testings

- Results : target quality reached and experimental validation of the simulation performed

Pilot - batch distillation column