01. SEDRE project

November 11th, 2021, the new collaborative project Energy Efficiency in Reactive Distillation (SEDRE) is launched. The main objective of this four-year ANR (French National Research Agency) project is to develop an innovative reactive distillation process by integrating the reactive distillation and internally heat-integrated distillation columns (HIDIC) in a single apparatus. This process intensification would result in 30% energy savings compared to a conventional reactive distillation. To carry out this large-scale project, the involvement of three complementary partners will be necessary: the Toulouse Chemical Engineering Laboratory (LGC), the Catalysis, Polymerization, Processes and Materials laboratory (CP2M) and Processium.

02. Complementarity: the project major asset

This significant project has been initiated by the Chemical Engineering Laboratory, the renowned reactive distillation expert, which will be responsible for designing, manufacturing and experimentally characterizing the HIDIC-R column internals.

Expert in the catalysis field, the main mission of CP2M is to functionalize the internals produced by the laboratory of Toulouse. The objectives are to deposit the catalyst on the structure, to optimize the deposition process and to verify the mechanical and chemical resistance and reactivity of the ICCIs (Innovative Catalytic Column Internals).

Finally, the Processium’s team of experts in industrial process design, development and optimization is in charge of modelling this internally heat-integrated distillation column (HIDIC-R).

03. Processium’s role in the SEDRE project

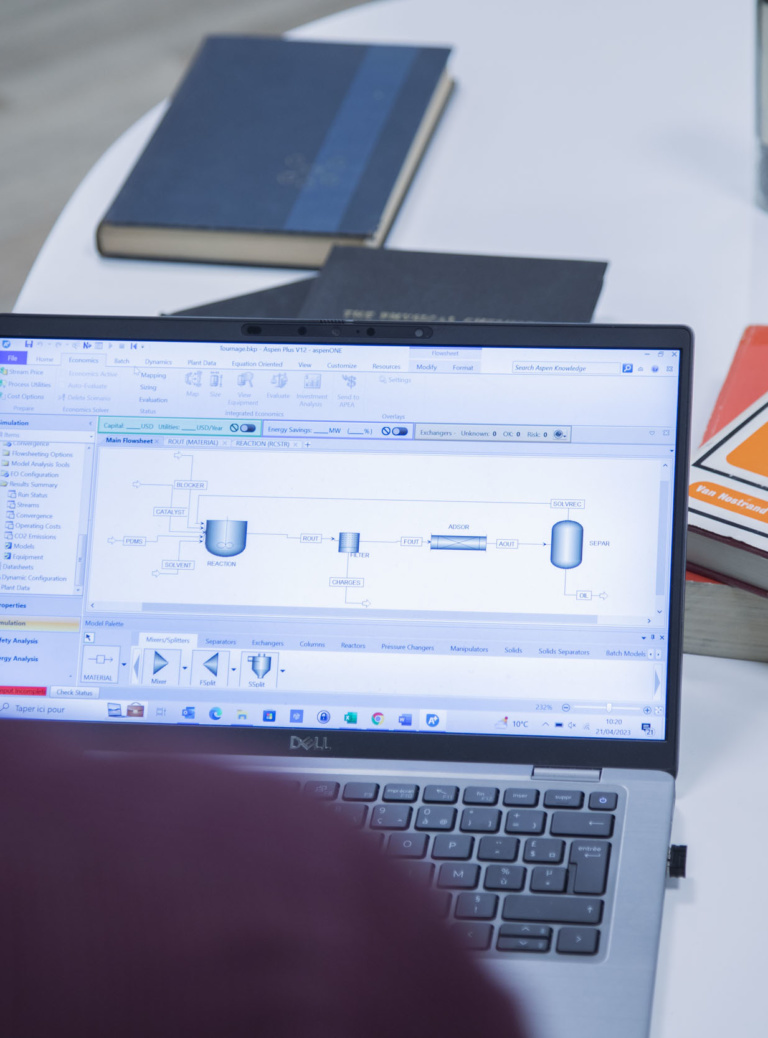

The company’s main objectives in this collaborative project are to model the HIDIC-R columns, simulate their energy performance and then, estimate their operating and production costs on an industrial scale.

In order to quantify this innovative process’ energy gain, Processium will need to model it using suitable encoding tools. Thanks to its expertise in carrying out technical and economic studies, Processium will also have to estimate the Reactive HIDIC operating and production costs on an industrial scale to conclude on the HIDIC-R interest over a conventional reactive distillation and a conventional sequence (reactor and distillation train).

This complex collaborative project is part of an industry’s drive to develop new technologies to radically improve manufacturing processes.